vsof-bs Samjin 403A

vsof-bs Samjin 403M

1. INTRODUCTION

1.1. General

This specification covers the design requirements and characteristics required of fiber optic splice closures to be used on fiber optic cables for branch joint in various installation conditions such as aerial, manholes, ducts, wall and direct buried applications. It is specially designed for FTTH network and applicable to multi branching installation by using Mid-Plate which is for increasing core capacity and complying with the requirements in each point of network. The flat type gasket ensures reliable sealing performance by preventing air and water leak and the cone type sealing socket provides easy and reliable installation. This closure has high mechanical strength against any environmental conditions. With this splice closure, you can improve your network system to the higher level.

1.2. Description

Fiber Optic Splice closure for fiber optic cable may be exposed to severe environmental conditions. The splice closure for fiber optic cable shall provide excellent durability and longterm reliability in those severe conditions.1.3. Reliability

The quality of a fiber optic splice closure is critical to reliable optical transmission performance. The product shall be produced with TL9000 certified production facilities and quality control system is applied the process from product design to packaging.

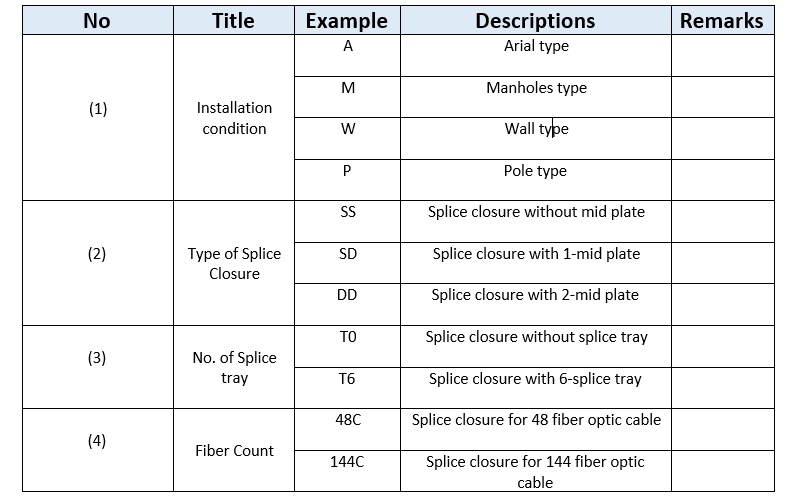

1.4. Classification

BS403A – A – SS – T2 – 48C

1.5. Terms and Definitions

1.5.1. SS-Type : Standard type splice closure without Mid-Plate1.5.2. SD-Type : Standard type splice closure with a total of 1 Mid-Plate

1.5.3. DD-Type : Standard type splice closure with a total of 2 Mid-Plate

1.6. Reference

Korea Telecom Generic Requirements KT-T24007-11-03 Korea industrial standard KS A 0101 Mathematical Symbols Korea industrial standard KS A 0102 Quantity Symbols, Unit Symbols and chemical Symbols Telcordia GR-771-core Generic Requirements for Fiber Optic Splice Closures.2. FIBER OPTIC SPLICE CLOSURE

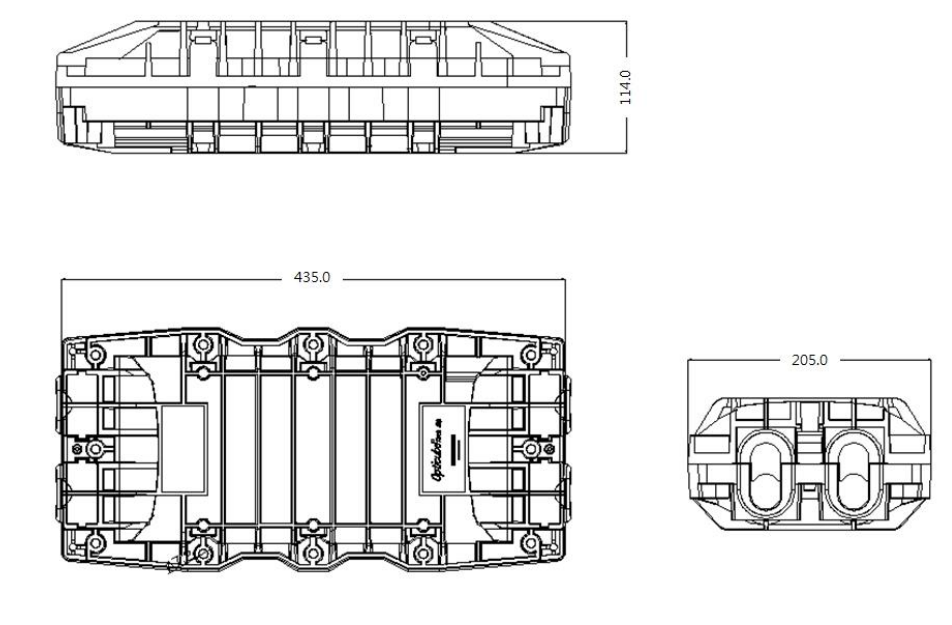

2.1. General

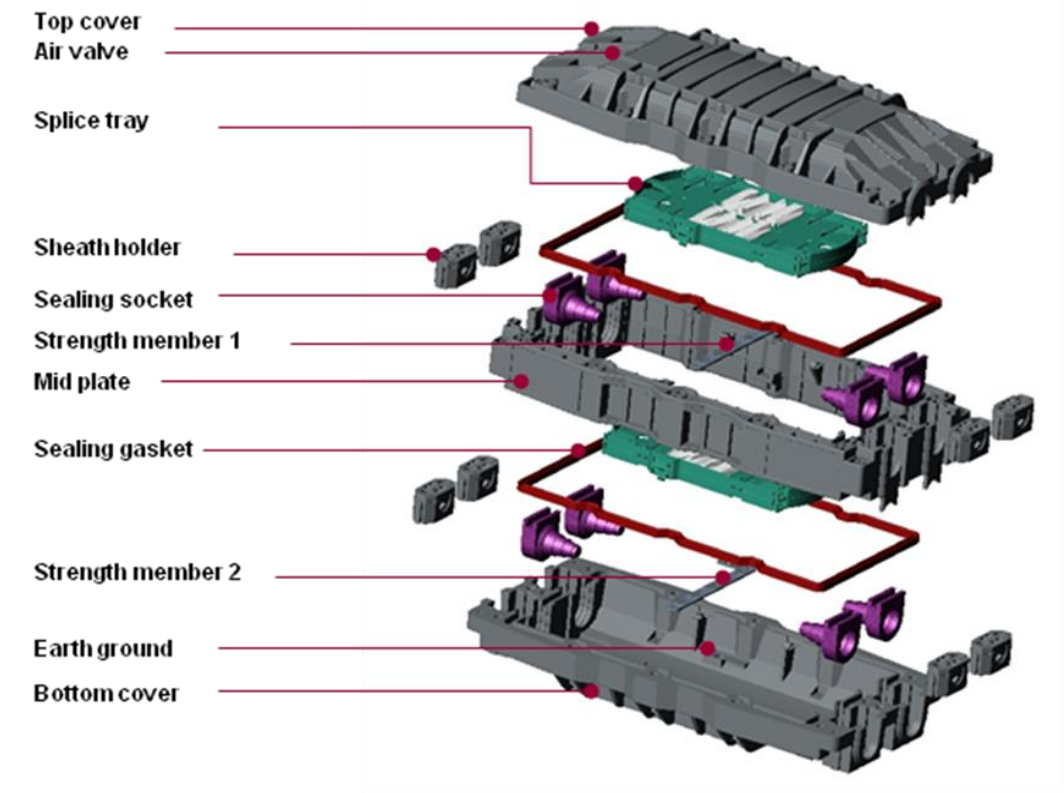

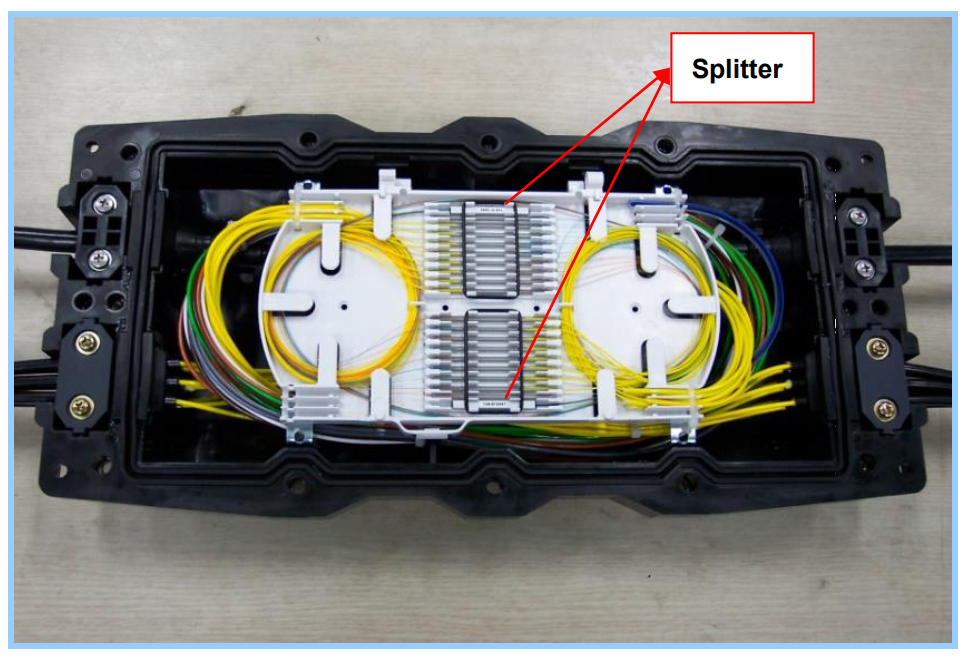

The closure consists of outer cases, gaskets, trays and inner kits. The closures have two main entry ports on each end. The outer cases consists of the upper and lower housing and constructed of highly chemical resistant material and attached a pressure valve on the upper housing. The trays are able to accommodate 24 individual fiber fusion splices2.2. Configuration

2.2.1. The closure has an air valve on its cover for checking air pressure drop.2.2.2. The ribbed body has high mechanical strength against impact and compression.

2.2.3. The closure has 2 inlet ports on each side and increase the number of port up to 12 ports by inserting Mid plate.

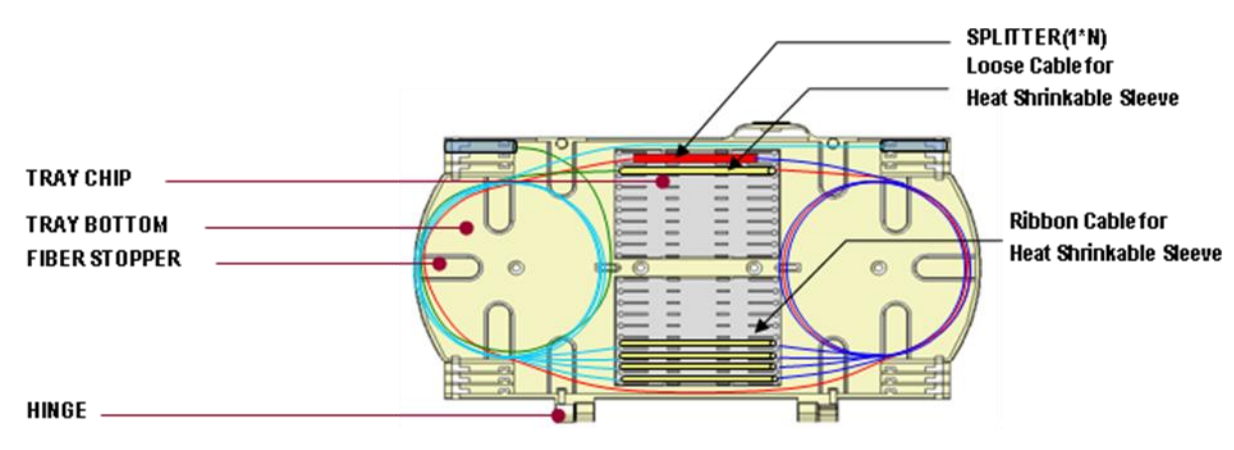

2.2.4. The 24F splice tray is applicable for both loose tube and ribbon fiber management.

2.2.5. The OSP cable clamping can be done by tension member gripper for clamping cables central strength member and sheath holder and adapter fitting each cable diameter for clamping cable sheath.

2.2.6. The LAP ground connector and ground wire are offered for grounding of the OSP cable.

2.2.7. One flat type gasket and the external screw bolts provide excellent tightness reliability.

2.2.8. Cone type sheath gasket is adjustable to fit any diameter cable.

2.2.9. The closure can be installed in aerial and manhole, pole with provide hangers

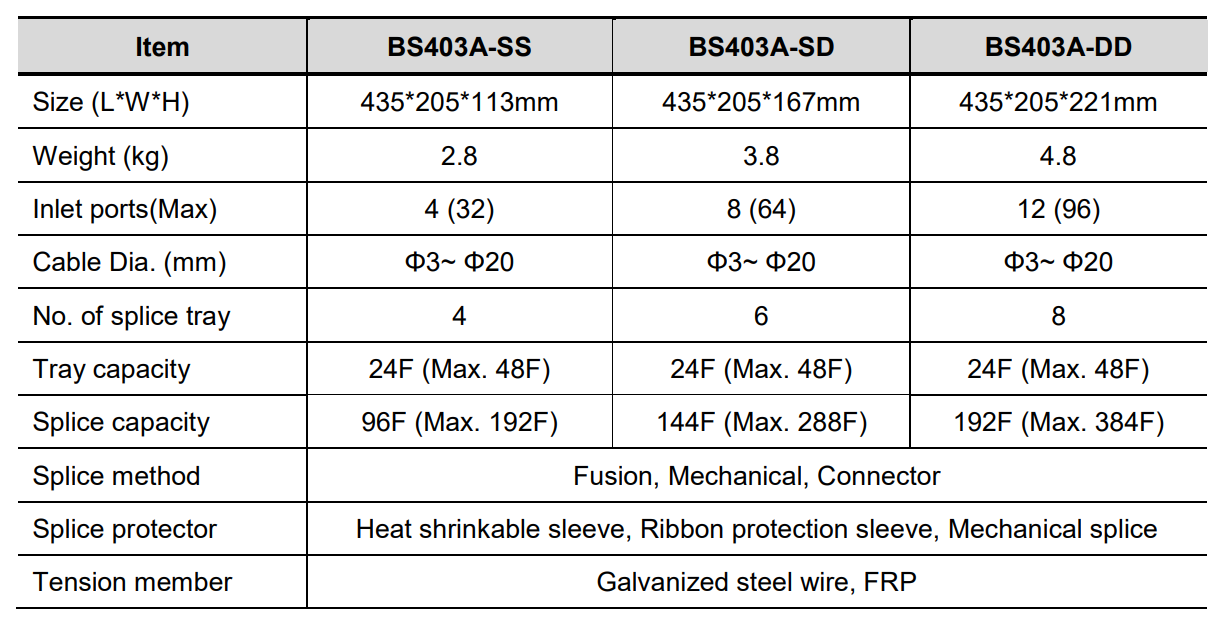

2.3. Specification

2.4. Feature